Products

Colored pellets and color masterbatches

These

colored plastic raw materials are indispensable for adding color to plastics

used in every aspect of our lives. We also have a lineup of color masterbatches

containing highly concentrated pigments and dyes for drop-in coloring to meet

all kinds of customer needs, including streamlining. We can handle a wide range

of target resins, from general-purpose resins to engineering plastics. We can

also accommodate special colorants, small-lot prototypes, small-lot products,

and quick delivery.

General-purpose resins:

PP,PE,PS,ABS,PET

Engineering plastics:

POM,PA,PC, m-PPE, PBT,PAR,PSF,PES,PPS,PEEK,PI,PEI,LCP etc.

High filler filling masterbatch

Metal-containing, high specific gravity compounds

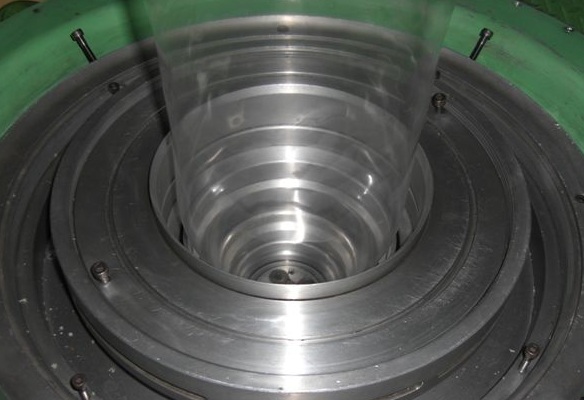

This is a metal-filled compound

made by using our proprietary compounding extruder specially developed for

high-filled compounds.

It can be used for various types of molding such as injection molding and extrusion molding, and is used for high design, electromagnetic shielding, ballast, and weights for fishing equipment.

We can also produce compounds made of other metals such as aluminum,

iron, cobalt, nickel, germanium, etc., according to various requests. Binder

resins can be selected from a variety of thermoplastic resins raging from

general-purpose resins to engineering plastics.

Please feel free to contact us.

Flame retardant masterbatch (halogen-free)

This is a new type of halogen-free flame retardant masterbatch that

passes various flame retardant standards with low additive concentration (2-5%)

to polyolefin fibers, films, nonwoven fabrics, etc. In addition, the flame

retardant component has excellent extraction resistance and has a HALS

skeleton, so it can simultaneously provide excellent light resistance and long-term thermal stability. Please

contact us about the applicable resins.

Flame retardancy standard(PO series): FMVSS 302 pass, Oxygen index: 24

to 28

Metal inactivation masterbatch

Metal inactivation suppresses the

generation of free radicals in the resin due to polyvalent metal ions in

minerals such as pigments and fillers and residual catalysts, and prevents

degradation of the resin due to polymer chain breakage, etc. They are also

attracting attention for preventing degradation over time due to the

migration of metal ions in applications where they come in contact with metals,

such as wire coatings and sliding resins.

Anti-blocking masterbatch

Deterioration prevention masterbatch

The occurrence of deterioration during inflation molding, T-die molding, and deformed extrusion molding not only causes appearance defects and foreign matter contamination, but also makes continuous molding difficult and reduces product yield. Especially when colorant and inorganic fillers are added, the occurrence of deterioration is noticeable.

Our deterioration prevention masterbatch is immiscible with the majority of polymers and moves at a high velocity during melt flow, forming a thin coating layer on the metal surface of the die. This layer directly contributes to the improvement of processability during extrusion molding.

It is mainly appropriate for

olefin resins and is available in two types: for T-die inflation molding and

for deformed extrusion and blow molding. (Engineering plastics with high

melting point are also available on request.)

Features

・Eradication of melt fractures (shark skin effect)

・Lessen the occurrence of deterioration

・High gloss surface finish

・Resin pressure drop and improvement of die output

・Faster start-up of manufacturing

・Reduced energy consumption

MFR reforming masterbatch for PP

Masterbatch of cross-linker for PE, EVA and rubber

This is the masterbatch of organic peroxides used for foam molding of PE and EVA and cross-linking of various rubbers. Usually, organic peroxides supplied in liquid form or in flakes with low melting point are difficult to handle. Masterbatching them greatly improves handling and can be used safely. You can choose the type and concentration of organic peroxide and carrier resins according to your requirements.

Thickening Masterbatch

Please feel free to contact us.

Access

Location

5-4-34,

Kano, Higashiosaka-shi, Osaka, 578-0901, Japan

Access

☐By train

〇about 10 minutes by taxi from Suminodo Station on the JR

Katamachi Line

〇about 10 minutes by taxi from Yoshita Station on the

Kintetsu Keihanna Line

☐By car

〇about 10 minutes from Hanshin Expressway No.13

Higashi-Osaka Line Mizuhai Exit

Disclaimer

We

shall not be held responsible for any trouble, loss or damage that may occur as

the result of using this site.